RIBOCONE

Classification

- Drying

- Mixing

- Food and Beverage

- Organic Chemicals

- Inorganic Chemicals

- Pharma and Nutraceutical

- Feed & Fertilizer

RIBOCONE is a multi-purpose equipment that can be used for mixing, drying, cooling, vacuum drying, filtration & (vacuum) drying and heating treatment (for decreasing of viable cells, for crystallization, for chemical reactions).

Features

- Drive and gearbox are located outside of the vessel in order to prevent risk of product contamination due to lubricants, amongst others

- Its special design increases the circulation of the product inside the vessel resulting in a fast mixing and fast drying

- Uniform moisture content and temperature of the product due to total mixing of the product

- Complete discharge of the final product from the bottom of the cone due to no bearing

- Sanitary type is available.

- Vacuum model avaiable

Typical Applications

Electronic and battery materials / Ceramics / Magnetic materials / Herbal medicine / Seasoning / Animal feed / Resin powder/APls

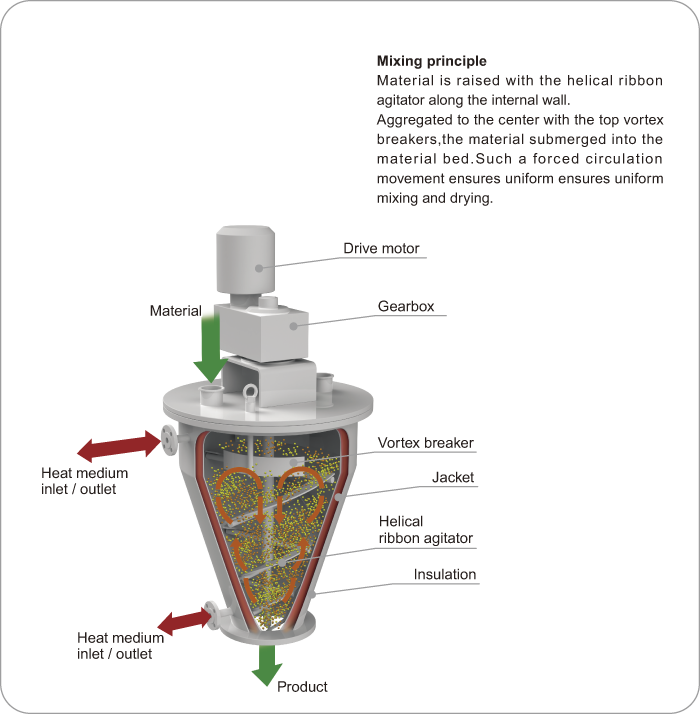

Operating Principle

The products are lifted upwards along the heated side wall,and with the help of the vortex breakers, the products will get sunk downwards again inside the process chamber resulting in a uniform temperature and product humidity across the entire product chamber. Its vertical design, and lack of bearing on the bottom of the vessel ensures a quick full product discharge.

Drive is located outside of the mixing chamber in order to prevent risk of product contamination due to lubricants, amongst others.

Drive is located outside of the mixing chamber in order to prevent risk of product contamination due to lubricants, amongst others.

| ADVANTAGE | REASON | RESULT | |

|---|---|---|---|

| 1 | Good mixing | Mixing of product with tailor made helical ribbon agitator |

Fast mixing

Fast drying

Fast reaction |

| Forced mixing with top vortex breakers | |||

| No dead space | |||

| 2 | No risk of product contamination due to lubricants, etc. | No gearbox inside the vessel | No contamination |

| 3 | High filling rate | No necessary extra space for gearbox or drive arm inside of the vessel | Less installation space required |

| 4 | Bottom discharge | No bottom bearing results in easy product dischage |

No product hold-up

Fast Different of valves available |

| 5 | Easy maintenance | Simple construction |

No complicated mechanism

Few consumables |

Video

Structural Image