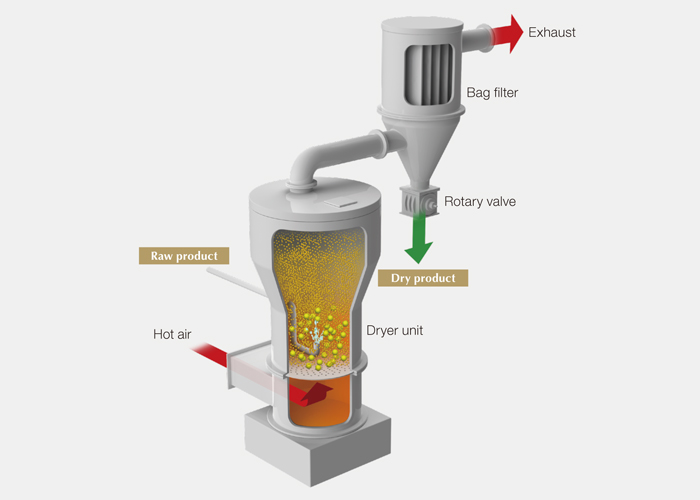

SLURRY DRYER

Classification

- Drying

- Inorganic Chemicals

The slurry or liquid to be dried is continuously supplied into the bed which contains 1-3mm diameter ceramic balls in fluidization to work as an auxiliary heating medium. The product supplied into the fluidized bed will get stick on the surfaces of the balls. The product will be instantly dried by the conduction heat from the heated balls and convection heat from the fluidization hot air and then peeled off the balls' surfaces by collision among them. The dried product will be conveyed by the fluidization gas to the recovery unit where it will be discharged.

Features

- The dried powder product obtained is close to its primary particle.

- High thermal efficiency

- Compact unit due to large thermal volumetric coefficient

- No need to atomize the slurry or liquid

- Easy cleaning

- Special design available

Typical Applications

Condenser materials / Barium titanate / Nickel hydroxide / Magnetic materials / Ceramics / Glass powders / Metal powders / Alumina / Titanium oxide / Zirconium / Calcium carbonate / Silicon carbide / Calcium silicate / Synthetic resins

Structural Image